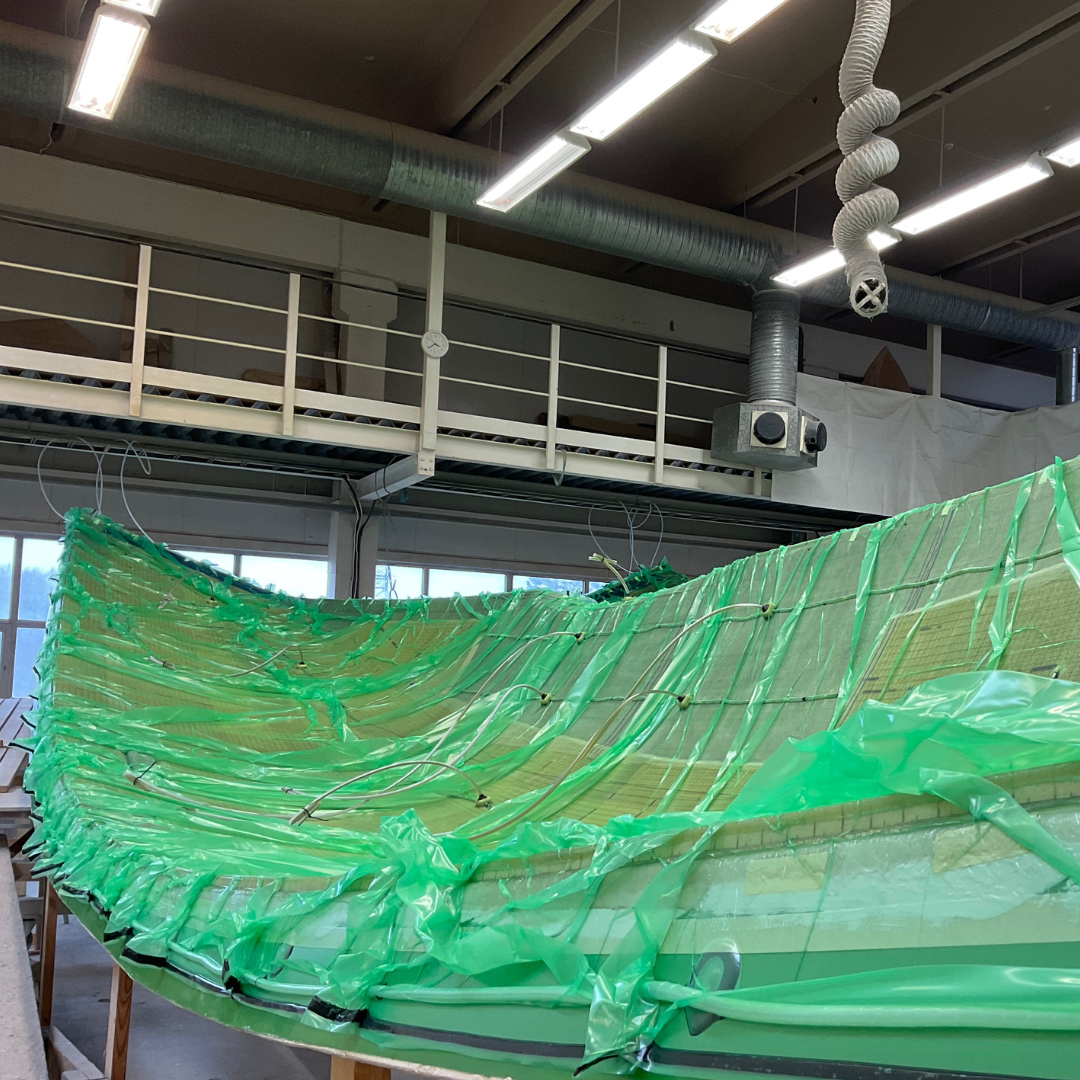

Saare yachts are built entirely with vinylester resin.

The entire laminate and all reinforcements, the laminates of the bulkheads, etc. have been made exclusively with this high-quality resin since 2016. Only very few shipyards do this in such an elaborate way.

Previously, our yachts were laminated with a high-quality ISO polyester resin, the two outer layers of the laminate structure were also laminated with vinyl ester resin to provide better osmosis protection.

With the introduction of the vacuum infusion process, we decided to use only vinyl ester resins.

Basically, the choice of laminating resin is of great importance.

Better quality on the one hand, different technical properties and a significantly higher price on the other hand have to be weighed against each other.

Choice of resin

The laminating resin in fiber composite materials such as those in a yacht (glass fiber reinforced plastic) fulfills two main functions. It must bind the reinforcement material, in yacht construction these are glass fiber mats, scrims and rovings, but also the sandwich materials. The resin must hold the reinforcements in the right position and connect them to each other to ensure the mechanical properties.

But the resin also contributes to a variety of advantages, such as corrosion and temperature resistance and electrical insulation. In combination with the sandwich material, it also provides excellent thermal insulation.

Of course, price also plays a major role in the selection of the resin.

Polyester resins

They are the resins most commonly used in yacht building. Most polyester resins consist of a polyester solution and typically styrene. Styrene is harmful to health and often evaporates for a long time. In some series yachts you can smell the styrene for a very long time.

Polyester resins are available in very different qualities. So-called orthopolyesters, for example, are inexpensive; they are not recommended for boat building, but are still used by many shipyards.

ISO-NPG resins are significantly better, stronger and, above all, more water-resistant / hydrolysis-resistant. They are also based on orthopolyester, but are significantly higher quality thanks to the appropriate additives. More expensive, but they are used successfully in yacht building, especially by good shipyards. However, they must be protected against diffusing moisture, which then leads to osmosis, by a sufficiently thick epoxy coating (2-component primer).

Vinylester resin

Vinylester resins combine the best properties of polyester and epoxy resins. They are much more mechanically resilient than polyester resins, but they are also more resistant and tougher than epoxy resins. Vinyl ester resins are a hybrid form of polyester resin that has been reinforced with epoxy.

They are more stretch-tolerant and can absorb shocks better, and they are also less prone to stress cracking than polyester resins. Vinyl ester resins are used as an alternative to epoxy resins due to their good mechanical properties and in particular their high osmosis resistance (around 300 times better than polyester resin).

They are much more expensive than polyester resins.

If you are interested in buying a yacht, ask the manufacturer or dealer for specific, contractually guaranteed information about the laminating resin used and the construction process.

On our Saare yachts, built after 2016, we provide a 5-year guarantee against the occurrence of osmosis in the hull and deck.