Why is a fixed rub rail integrated on a Saare yacht?

A rub rail on the outside of the hull is generally a good thing. It is very helpful when mooring in narrow boxes with stern posts, even if you are moored alongside the pier or a neighboring boat. Harbour maneuvers alone or with a small crew become much easier and safer. In any case, the outer skin is protected and protected from damage.

If you then make sure that the fenders rest on the rub rail and not on the hull, the fenders cannot leave dull scuff marks on the gelcoat.

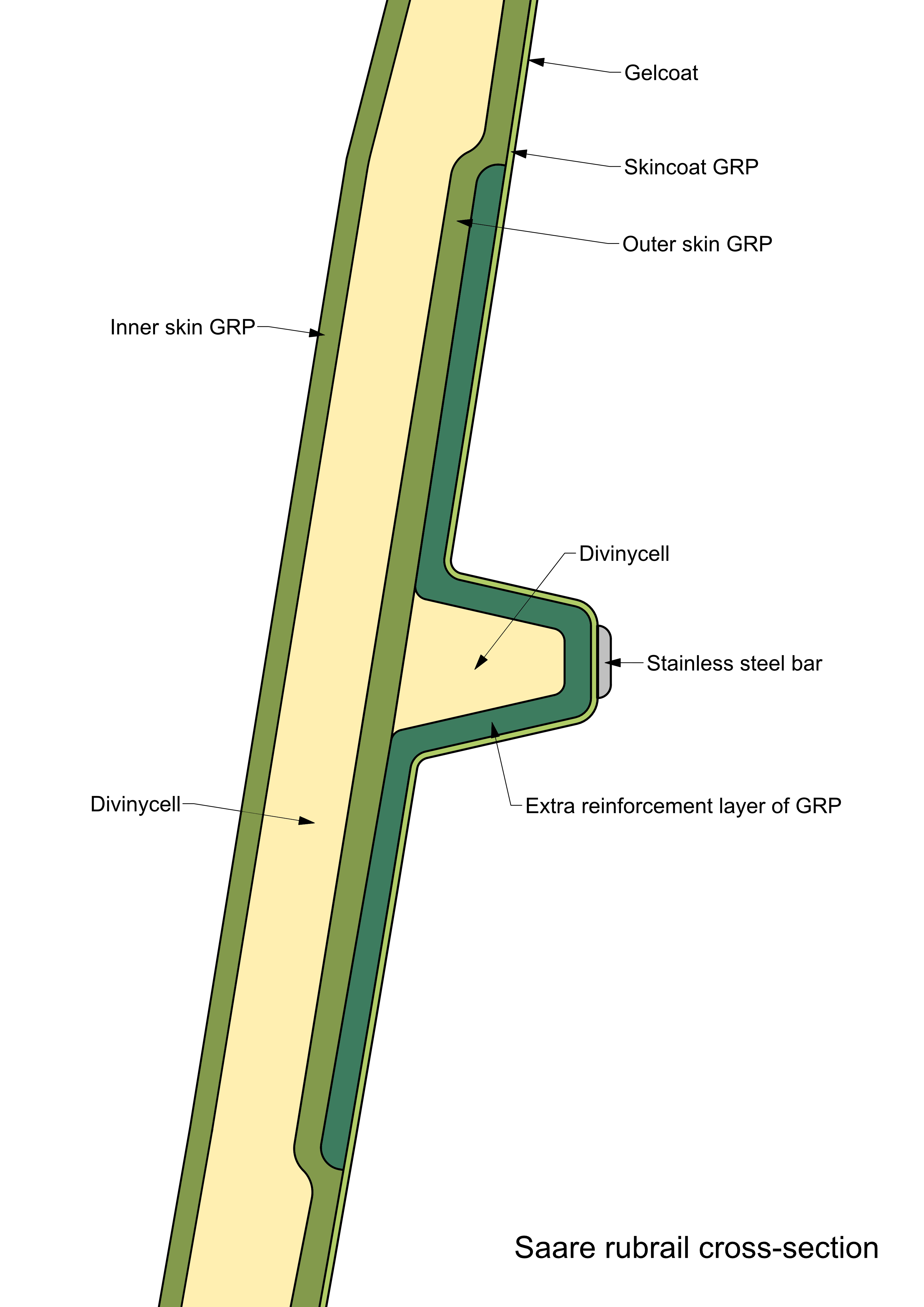

The rubbing strip of a Saare is also protected with a profile made of V4A stainless steel. This means you can lie directly on a wooden post without getting a scratch.

Of course, you can also later install a wooden or rubber rubbing strip on any yacht. However, you then have to drill a lot of holes in the area for attachment to the outer skin.

Our skirting board profile is integrated into the design. This not only looks very elegant, but is also very stable and also acts like a solid frame in the outer skin.

This area is first coated with gelcoat. Fully done by hand, the narrow and narrow profile cannot be reliably processed with a spray gun with a consistent layer thickness.

Then, again by hand, several layers of glass mat with vinyl ester resin are laminated into the profile using the hand-laying process. The profile is then completely filled and laminated again with 2 layers in order to then have a flat surface for the vacuum infusion process. From there, the vacuum infusion process continues to build the hull.

The rub rail also stiffens the hull like a surrounding ring beam.